On Wednesday, April 17th, I met up with Marti, Nacho, and Andoni for my visit to the Sammic Headquarters. Sammic is the main sponsor of the Basque Stage and is one of the main reasons for this great opportunity to live in the Basque Country. Sammic manufactures commercial kitchen equipment and distributes their products to all over the world. The first piece of kitchen equipment that started it all was a potato peeler. No I’m not talking about one of those small peelers that you use to peel potatoes and other vegetables, but an actually machine that you place potatoes in and then it spins the potatoes and peels every potato until its skin free. Since then they have expanded their catalog to equipment from glasswear washers to vacuum package machines.

Upon arriving to the headquarters in the beautiful town of Azkoitia, Spain, I meet Amaia Altuna who works in Marketing. She is this very nice lady that seems to know about the company inside and out. She introduces me to my tour guide, Asier Bereziartua, and then it was off to see the factory where all the magic happens.

Asier works in the office of the factory and is the man that takes all the calls when it comes to information about the equipment and specific pieces and parts for all of their products. His English was pretty excellent so that made the tour that much more informative and exciting for me!

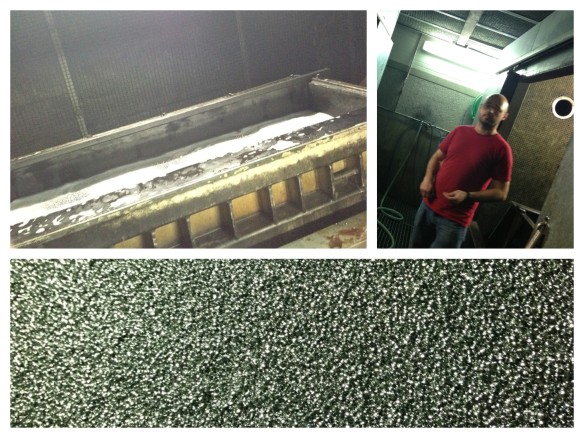

We start off on the main floor of the factory. The first thing he shows me where they melt down all the pieces of aluminum to form into specific pieces for each of their products. He asked me if I had seen the film “The Terminator” and then he has me look into this deep crevice that is filled with melted metal. The reference he makes is pretty perfect as it actually does look like T-1000 from the movie. It was a beautiful sight and almost hypnotizing as I just wanted to touch the liquid as it looked so pretty. But of course I knew that the consequences wouldn’t be the greatest. He then shows me a big pile of equipment parts that was not usable and they reuse and recycle any scrap metal to form into new pieces that they can utilize.

We continue on the tour and he shows me some parts for their potato peelers that they made that morning. Amazing to see all the work they crank out in the matter of a couple hours. Next he shows me the room that these newly formed parts go to get buffered and polished up to look all nice for assembling.

We pass by the assembly line where we see workers putting together different equipment from dishwashers of many sizes to potato peelers. I noticed that these machines are all being put together all by hand and I ask Asier if all of their products are put together like this. He confirms that everything that comes out of their factory is put together by hand and then every single piece of equipment is tested to see if they are working in perfect condition before they distribute them to establishments. I find this to be an amazing thing about Sammic because it really shows that this company really care and have a lot of pride for all their products that leaves their factory.

Asier then takes me to my favorite portion of the tour, the development area. This is where they take equipment concepts and then build them to test them out. The piece of equipment he shows me that is was in the middle of development was a washing machine. It looked like any other normal commercial washing machine but he explains to me that there is a special part on the top of the machine that takes all the steam that the dishwasher expels once you open it and suck all of it up and then recycles it and turns it into clean, usable water for the next batch of dishes. I found this to be such a great idea and very cool to see that this sort of machine is being developed.

Next, we head to the testing area where they test their equipment for a straight 24 hours. They developed these machines that press the ‘on’ button on their equipment every minute to see how well they run to make sure they are working properly.

To conclude our tour, we leave the factory and he shows me other parts of the Sammic Headquarters like the marketing office and the offices where the engineers work. Not too shabby place to work it seems like!

I am very excited to be working with such a great company and really appreciative of all they have made possible for me and all of the previous Basque Stages. Special thanks to Amaia, Asier and everyone at Sammic for having me visit their facility. I am looking forward to trying out some of the products that this company produces and see them in action!

Pingback: Pintxo Roundup: Kallos de Bacalao al Pil Pil | JustinCLegaspi

Pingback: The Toys of Xarma Jatetxea | JustinCLegaspi